Belt grinding is the most efficient choice for precision grinding because of the high surface quality, lower energy, and tooling costs, and tight tolerance. A switch between high stock removal and fine finishing can be done by a fast abrasive belts change. By working over the full width of the material in a cold process environment, low material tension will be added. Famak precision grinding machines are high tolerance level, allowing for precision up to 0.02 mm.

There are quite some widths available, ranging from 650 mm up to 2200 mm. The workpieces get machined to very close tolerances and high-quality finishes.

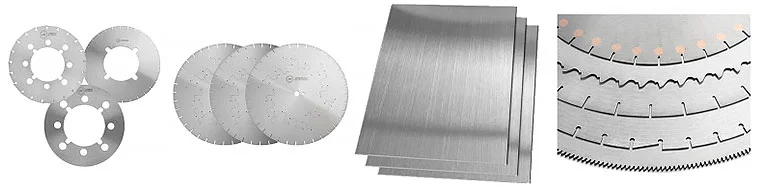

The wide range of parts from various metals for precision grinding includes: titanium, stainless steel, steel, aluminum, brass, zirconium or molybdenum, and many more. This type of grinding results in a high-quality surface. The work is often done for manufacturing industries related who need high tolerance.

to serve you

Get more detailed information and price quotes about our products

© Copyright 2024. GEC MACHINE – Metal-Wood Working Machineries and Endusing Solutions

Design: Elnur Ahmadov